Chicago Restaurant Health Code 4-601.11 Compliance Guide

Understanding and maintaining compliance with Chicago health code 4-601.11 is critical for every restaurant operating in the city. This regulation governs equipment and surface cleanliness standards that directly impact your health inspection results and operating license. Whether you’re opening a new restaurant, preparing for an inspection, or maintaining daily compliance, this comprehensive guide explains everything you need to know about code 4-601.11, common violations, and how to stay compliant.

What is Chicago Health Code 4-601.11?

Chicago Municipal Health Code 4-601.11, formally titled “Equipment, Food-Contact Surfaces, and Utensils – Cleaning,” establishes mandatory standards for maintaining clean and sanitary equipment in food service establishments. This code is part of the broader Chicago Food Protection Ordinance and aligns with the FDA Food Code while addressing Chicago-specific requirements.

The regulation mandates that:

All equipment and food-contact surfaces must be clean to sight and touch. Equipment food-contact surfaces and utensils must be cleaned throughout the day as necessary to prevent accumulation of food particles and debris. Food-contact surfaces of cooking equipment and pans must be kept free of encrusted grease deposits and other accumulated soil. Non-food-contact surfaces must be kept free of an accumulation of dust, dirt, food residue, and debris.

The key phrase “clean to sight and touch” means surfaces cannot have visible soil, residue, or buildup when visually inspected, and they should not leave residue when physically touched. This standard applies continuously—not just before inspections.

Who Must Comply:

All food service establishments operating in Chicago including full-service restaurants, fast-casual eateries, quick-service restaurants, food trucks and mobile vendors, catering operations, bakeries and cafes, bars serving food, institutional kitchens (schools, hospitals), and grocery stores with prepared food sections.

There are no exemptions based on size, cuisine type, or service model. Every establishment preparing, serving, or storing food must comply with 4-601.11 standards.

Why Code 4-601.11 Matters for Your Restaurant

Impact on Health Inspections

Code 4-601.11 violations are among the most commonly cited issues during Chicago Department of Public Health (CDPH) inspections. Violations are categorized as:

Critical violations directly linked to foodborne illness (example: food residue on cutting boards, grease buildup on cooking surfaces). These violations require immediate correction and can result in point deductions on your inspection score.

Non-critical violations that could become health hazards if uncorrected (example: dust accumulation on non-food surfaces, minor equipment exterior soil). While less severe, accumulating multiple non-critical violations affects your overall rating.

Chicago’s inspection system uses a point-based scoring where violations result in deductions. Restaurants scoring below certain thresholds face:

- “Pass with Conditions” rating (requires follow-up inspection)

- “Fail” rating (requires immediate corrections before reopening)

- Potential closure for severe or repeated violations

- Public posting of inspection results affecting reputation

Financial Consequences

Non-compliance with 4-601.11 creates multiple financial burdens:

Reinspection fees: $100-$500 for required follow-up inspections after violations

Lost revenue: Closure orders or negative inspection publicity reducing customer traffic by 20-40% in following weeks

Cleaning costs: Emergency deep cleaning services costing $800-$2,000 to address violations before reinspection

Legal liability: Foodborne illness outbreaks linked to unsanitary equipment resulting in lawsuits, settlements, and reputation damage

License issues: Repeated violations jeopardizing license renewal or resulting in suspension

Maintaining compliance is far more cost-effective than addressing violations after they occur.

Reputation Protection

Chicago posts restaurant inspection results publicly on the CDPH Food Protection website. Customers increasingly check inspection scores before dining, and negative results spread quickly through review sites and social media.

Restaurants with consistent violations see measurable impacts including decreased reservations and foot traffic, negative online reviews mentioning cleanliness concerns, difficulty attracting top culinary talent who want to work in reputable establishments, and challenges securing catering contracts or event bookings requiring proof of compliance.

Your restaurant’s reputation is inseparable from its cleanliness standards. Code 4-601.11 compliance protects the business you’ve worked hard to build.

Equipment Categories Covered Under 4-601.11

The code applies to all equipment and surfaces in your food preparation and service areas. Understanding which items require compliance helps you develop thorough cleaning protocols.

Food-Contact Surfaces (Highest Priority)

These surfaces directly touch food during preparation, cooking, or serving and require the most rigorous cleaning:

Preparation equipment: Cutting boards, prep tables, food processors, mixers, slicers, food scales

Cooking surfaces: Griddles, grill grates, oven interiors, fryer baskets, woks, saute pans, stock pots

Serving equipment: Serving utensils, tongs, ladles, serving trays, buffet containers

Storage items: Food storage containers, ingredient bins, shelf surfaces in walk-in coolers

Dispensing equipment: Ice machines, beverage dispensers, coffee makers, condiment containers

Food-contact surfaces must be cleaned and sanitized throughout service—not just at day’s end. Between tasks involving different food types (especially raw proteins and ready-to-eat foods), surfaces require cleaning to prevent cross-contamination.

Cooking Equipment

Cooking equipment accumulates grease, carbonization, and food particles requiring specialized cleaning:

Ovens and ranges: Interior surfaces, racks, burners, drip pans

Fryers: Fry pots, heating elements, filtration systems

Grills and griddles: Cooking surfaces, grease traps, backsplashes

Steam equipment: Steam tables, steamers, combination ovens

Specialty equipment: Salamanders, broilers, char-broilers, rotisseries

Code 4-601.11 specifically prohibits “encrusted grease deposits” on cooking equipment. Daily degreasing and weekly deep cleaning prevent buildup that violates this standard.

Refrigeration and Storage

Temperature-controlled equipment requires cleanliness to maintain food safety:

Walk-in coolers and freezers: Interior walls, floors, shelving, door seals

Reach-in refrigerators: Shelves, drawers, door gaskets, drip pans

Display cases: Glass surfaces, lighting fixtures, product holders

Dry storage: Shelving units, storage racks, ingredient containers

Spills, drips, and condensation must be cleaned immediately. Scheduled deep cleaning prevents mold, odors, and bacterial growth in refrigeration units.

Utensils and Smallwares

All utensils contacting food during preparation or service fall under 4-601.11:

Kitchen utensils: Knives, spatulas, whisks, tongs, ladles, measuring cups

Smallwares: Pans, bowls, strainers, colanders, baking sheets

Serving items: Plates, bowls, silverware, glasses, serving vessels

Preparation tools: Cutting boards, mandolins, peelers, graters

The three-compartment sink procedure (wash, rinse, sanitize) or high-temperature dishwasher are approved methods for utensil cleaning meeting 4-601.11 standards.

Non-Food-Contact Surfaces

While these surfaces don’t directly touch food, the code requires them to be “free of accumulation of dust, dirt, food residue, and debris”:

Equipment exteriors: Refrigerator doors, oven exteriors, mixer casings

Structural elements: Walls, ceilings, floors, baseboards

Ventilation: Hood exteriors, duct exteriors, exhaust fans

Fixtures: Light fixtures, hand sinks, employee facilities

Non-food-contact surface violations are typically non-critical but accumulating multiple violations increases inspection point deductions.

Common Code 4-601.11 Violations in Chicago Restaurants

Understanding the most frequent violations helps you proactively address compliance issues before inspections.

Top 5 Critical Violations

1. Food residue on cutting boards and prep surfaces

Inspectors frequently cite cutting boards with visible knife marks filled with food particles, colored staining from raw proteins, and odors indicating bacterial growth. Even “clean” cutting boards failing the sight and touch test violate 4-601.11.

Prevention: Replace cutting boards showing deep scoring. Sanitize cutting boards between tasks, especially after raw protein contact. Consider color-coded boards for different food types to prevent cross-contamination.

2. Grease buildup on cooking equipment

Encrusted grease on griddles, fryers, ovens, and ranges is one of the most common critical violations. Carbonized grease is difficult to remove and clearly visible to inspectors.

Prevention: Daily degreasing of all cooking surfaces. Weekly deep cleaning using commercial degreasers. Professional hood and equipment cleaning quarterly or as needed based on cooking volume.

3. Dirty food slicers and processors

Equipment with moving parts and crevices (slicers, mixers, food processors) accumulate food particles in hard-to-reach areas. Inspectors disassemble equipment during inspections to check hidden surfaces.

Prevention: Complete disassembly and cleaning after each use per manufacturer instructions. Document cleaning with logs showing date, equipment, and staff member responsible.

4. Soil accumulation in ice machines

Ice machines contact food (ice) and require strict cleanliness. Violations include mold in ice bins, mineral deposits on ice makers, and debris in ice storage areas.

Prevention: Daily wiping of ice bin interiors. Weekly sanitization of all ice-contact surfaces. Monthly deep cleaning and descaling. Professional commercial cleaning service semi-annually.

5. Food residue in refrigeration units

Spills, drips, and expired items in coolers create bacterial growth and odors violating 4-601.11 standards.

Prevention: Immediate cleanup of spills. Daily checks for expired items. Weekly removal of all items for thorough cleaning. Monthly deep cleaning of shelves, walls, and floors.

Common Non-Critical Violations

Dust on non-food surfaces: Accumulation on top of equipment, light fixtures, or ventilation hoods

Equipment exterior soil: Grease splatters, fingerprints, or food residue on refrigerator doors, oven exteriors, or mixer casings

Floor and wall cleanliness: Food debris in corners, grease on walls near cooking equipment, or stains on floors

Shelf cleanliness: Dust or spills on dry storage shelving or prep area shelves

While non-critical, multiple violations compound to lower inspection scores and create conditions leading to critical violations if unaddressed.

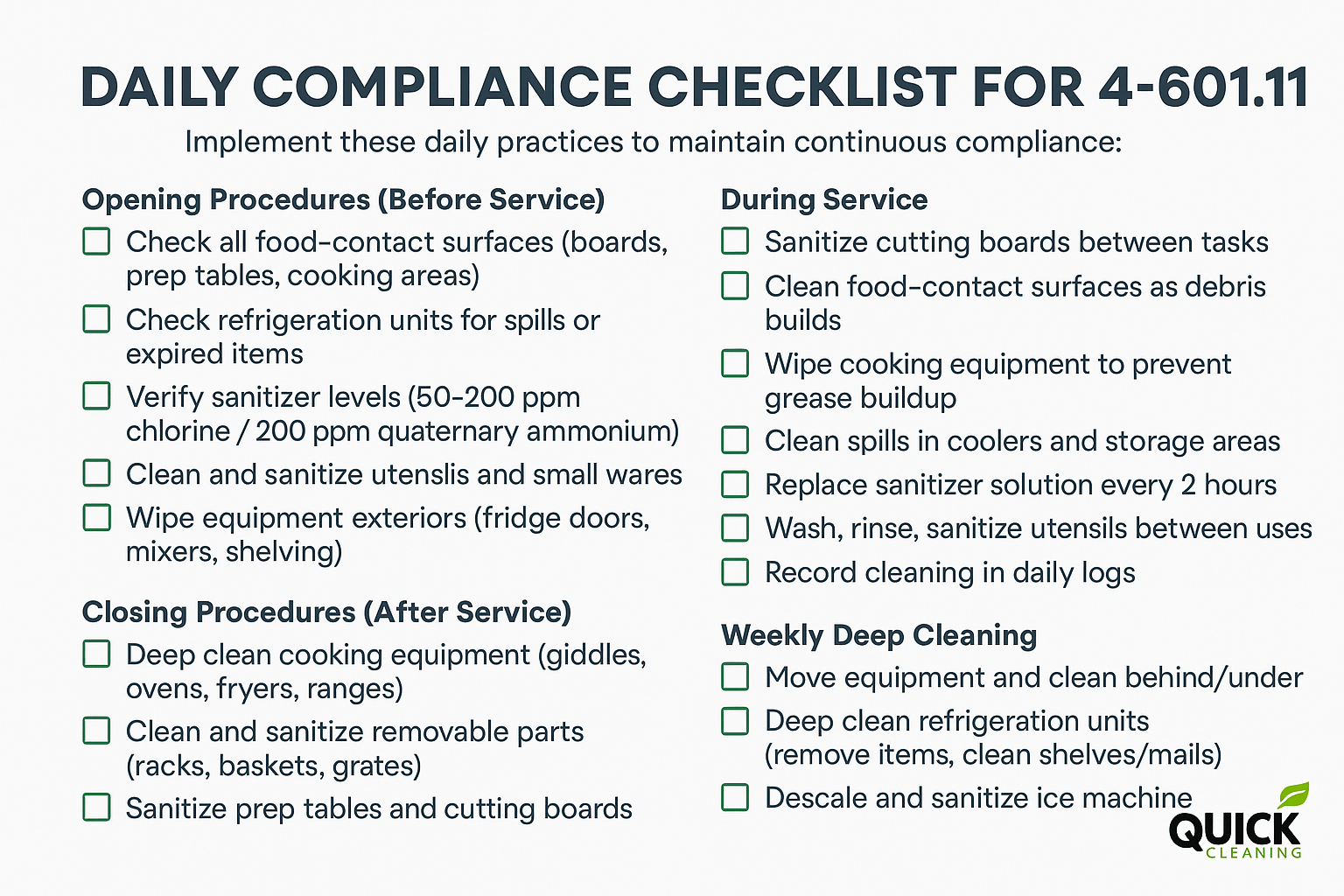

Daily Compliance Checklist for 4-601.11

Implement these daily practices to maintain continuous compliance:

Opening Procedures (Before Service):

☐ Inspect all food-contact surfaces for cleanliness (cutting boards, prep tables, cooking surfaces)

☐ Check refrigeration units for spills or expired items

☐ Verify sanitizer concentration in three-compartment sink (50-200 ppm chlorine or 200 ppm quaternary ammonium)

☐ Clean and sanitize all utensils and smallwares from previous day

☐ Wipe down equipment exteriors (refrigerator doors, mixer casings, shelving)

During Service:

☐ Clean and sanitize cutting boards between tasks and food types

☐ Clean food-contact surfaces as food particles accumulate

☐ Wipe cooking equipment to prevent grease buildup

☐ Clean spills immediately in refrigeration and storage areas

☐ Replace sanitizer solution every 2 hours or when visibly soiled

☐ Wash, rinse, and sanitize utensils between uses

Closing Procedures (After Service):

☐ Deep clean all cooking equipment (griddles, ovens, ranges, fryers)

☐ Remove, clean, and sanitize removable parts (fryer baskets, oven racks, burner grates)

☐ Clean prep surfaces and cutting boards

☐ Empty, clean, and sanitize three-compartment sink

☐ Clean floors including corners and under equipment

☐ Wipe down all equipment exteriors

☐ Remove trash and clean trash storage areas

☐ Document cleaning completion in daily logs

Weekly Deep Cleaning:

☐ Move equipment to clean behind and underneath

☐ Deep clean refrigeration units (remove all items, clean shelves, walls, floors)

☐ Descale and sanitize ice machines

☐ Clean walls and baseboards near cooking equipment

☐ Detail clean hard-to-reach areas (under counters, between equipment)

☐ Professional restaurant hood cleaning if needed based on cooking volume

Download or Save the Check list Below:

Cleaning Products and Methods for Compliance

Using appropriate cleaning products and methods ensures effective compliance with 4-601.11 standards.

Approved Cleaning Agents

For food-contact surfaces:

Use EPA-registered sanitizers approved for food-contact use including chlorine-based sanitizers (50-200 ppm concentration), quaternary ammonium compounds (200 ppm concentration), and iodine-based sanitizers (12.5-25 ppm concentration). Always follow manufacturer instructions for proper concentration, contact time, and temperature.

For non-food-contact surfaces:

Commercial degreasers for removing cooked-on grease and carbon, all-purpose cleaners for general surface cleaning, and floor cleaners appropriate for your flooring type (tile, quarry tile, epoxy).

For equipment:

Manufacturer-approved cleaning products for specialized equipment like ovens, fryers, and ice machines. Using wrong products can damage equipment and void warranties.

Three-Compartment Sink Procedure

The three-compartment sink is the approved method for manual utensil and equipment cleaning:

Sink 1 – Wash: Hot water (minimum 110°F) with detergent. Scrub items to remove all visible soil and food particles.

Sink 2 – Rinse: Clean hot water to remove detergent and loosened soil. No soap or chemicals in rinse water.

Sink 3 – Sanitize: Chemical sanitizer at proper concentration and temperature or hot water (minimum 171°F) for heat sanitization. Submerge items completely for required contact time (typically 30 seconds for chemical, 30 seconds for heat).

Air Dry: Place sanitized items on clean, sanitized surface to air dry. Do not towel dry as this can recontaminate items.

Test sanitizer concentration before each use with test strips. Document concentration in logs for inspection records.

High-Temperature Dishwashers

Commercial dishwashers meeting NSF/ANSI Standard 3 are approved for cleaning and sanitizing:

Requirements: Wash temperature minimum 150°F, rinse temperature minimum 180°F for sanitization, and proper chemical dispensing if using low-temperature machine.

Operation: Scrape excess food before washing, avoid overloading racks, and verify temperature with built-in thermometers or external monitoring.

Maintenance: Daily cleaning of machine interior, weekly deliming, and monthly professional service.

Document dishwasher temperatures daily to prove compliance during inspections.

Professional Cleaning Services for 4-601.11 Compliance

While daily staff cleaning is essential, professional commercial kitchen cleaning services provide deep cleaning that exceeds staff capabilities and ensures continuous compliance.

When to Hire Professional Cleaners

Monthly or quarterly deep cleaning: Professional services handle tasks beyond daily capabilities including hood system cleaning per NFPA 96, equipment disassembly and detailed cleaning, floor stripping and resealing, and wall and ceiling degreasing.

Pre-inspection preparation: If your inspection is scheduled or overdue, professional pre-inspection cleaning addresses all areas inspectors examine, provides documented proof of professional service, and gives confidence entering inspection.

Violation correction: If you received violations requiring correction before reinspection, professional cleaners ensure all cited issues are addressed properly, provide before/after documentation, and meet CDPH standards for reinspection approval.

New restaurant setup: Before opening, professional cleaning ensures all equipment meets “clean to sight and touch” standards, establishes baseline cleanliness, and creates good habits from day one.

What Professional Services Include

Reputable commercial kitchen cleaning companies provide:

Food-contact surface sanitization: Deep cleaning and sanitizing of all prep tables, cutting boards, equipment, and utensils using ANSI/NSF approved methods

Cooking equipment degreasing: Removal of encrusted grease from ovens, fryers, griddles, ranges, and all cooking surfaces using commercial-grade degreasers and steam cleaning

Hood system cleaning: NFPA 96 compliant cleaning of exhaust hoods, ducts, fans, and rooftop components with certification and documentation

Refrigeration deep cleaning: Complete cleaning of walk-ins, reach-ins, and display cases including shelves, walls, floors, and door seals

Floor cleaning: Degreasing, scrubbing, and sanitizing of kitchen floors including drains, corners, and under equipment

Documentation: Detailed service reports, before/after photos, and chemical concentration logs for your inspection records

Choosing the Right Professional Service

Look for cleaning companies with:

✅ ServSafe or equivalent food safety certification showing staff understands food service sanitation

✅ Chicago health code knowledge including 4-601.11 and CDPH inspection standards

✅ NFPA 96 certification for hood cleaning if needed

✅ Commercial liability insurance protecting your business

✅ Background-checked staff you can trust in your facility

✅ Documented service records providing proof of compliance

✅ Flexible scheduling working during your closed hours

✅ Positive reviews from other Chicago restaurants

Professional cleaning is an investment in compliance that prevents costly violations, closures, and reputation damage.

Need professional restaurant cleaning that ensures 4-601.11 compliance? Quick Cleaning specializes in Chicago restaurant deep cleaning meeting all health code standards. Get a free quote →

Documentation and Record-Keeping

Maintaining cleaning documentation proves your compliance efforts to inspectors and protects you during disputes.

Essential Cleaning Logs

Daily cleaning checklist: Document completion of opening, during-service, and closing cleaning tasks with date, staff initials, and supervisor verification.

Equipment cleaning log: Record date, equipment cleaned, method used, staff member, and supervisor verification for specialized equipment requiring detailed cleaning.

Sanitizer concentration log: Document test strip readings for three-compartment sink and other chemical sanitizers showing proper concentration three times daily (opening, mid-service, closing).

Temperature log: Record dishwasher wash and rinse temperatures daily, refrigeration unit temperatures twice daily, and cooking equipment temperatures as needed.

Professional service records: Keep all invoices, service reports, and certifications from professional cleaning companies including hood cleaning certificates, equipment service records, and pest control documentation.

During Inspections

Present documentation proactively when inspectors arrive:

Show organized binder or digital records demonstrating consistent cleaning practices, provide professional cleaning service records showing scheduled maintenance, and share sanitizer and temperature logs proving compliance monitoring.

Documentation doesn’t prevent inspections from finding violations, but it demonstrates good faith efforts at compliance and may influence inspector discretion on borderline issues.

Resources and Additional Information

Official Chicago Resources

Chicago Department of Public Health Food Protection:

Website: www.chicago.gov/cdph

Information on inspections, violations, and compliance

Chicago Food Protection Ordinance:

Full text of health code including 4-601.11 available on CDPH website

Inspection Results:

Search your restaurant’s inspection history: Chicago Food Inspections Portal

Federal Resources

FDA Food Code:

National standards influencing Chicago’s code: FDA Food Code 2022

CDC Food Safety Resources:

Best practices for food service sanitation: CDC Food Safety

Professional Associations

Illinois Restaurant Association:

Industry support, training, and advocacy: www.illinoisrestaurants.org

National Restaurant Association:

ServSafe certification and food safety training: www.restaurant.org

Maintaining Continuous 4-601.11 Compliance

Chicago health code 4-601.11 compliance isn’t achieved once—it requires daily attention, proper training, thorough cleaning practices, and professional support. Restaurants maintaining continuous compliance avoid violations, protect their reputation, create safer food for customers, and operate with confidence knowing they meet city standards.

Key takeaways:

✅ Understand what 4-601.11 requires for your specific equipment and surfaces

✅ Implement daily cleaning protocols addressing all food-contact and non-food-contact surfaces

✅ Train staff on proper cleaning methods including three-compartment sink procedure

✅ Use approved cleaning products and sanitizers at correct concentrations

✅ Document cleaning activities with logs proving compliance

✅ Schedule professional deep cleaning monthly or quarterly

✅ Address violations immediately and correct underlying issues

✅ Stay informed about regulation updates and inspection trends

Your restaurant’s success depends on cleanliness standards that keep customers safe and inspectors satisfied. Invest in compliance today to avoid costly consequences tomorrow.

Need Expert Restaurant Cleaning That Ensures Health Code Compliance?

Quick Cleaning specializes in Chicago restaurant cleaning meeting all health code 4-601.11 standards. Our certified team provides:

✅ Complete kitchen deep cleaning and sanitization

✅ Food-contact surface cleaning meeting ANSI/NSF standards

✅ Cooking equipment degreasing removing encrusted buildup

✅ Hood system cleaning with NFPA 96 certification

✅ Pre-inspection preparation and violation correction

✅ Documented service records for your compliance files

✅ 24/7 emergency cleaning when you need it most

Over a decade serving Chicago restaurants. 235+ five-star reviews. Licensed, bonded, and insured.

Get your free restaurant cleaning quote: (773) 800-2524